Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

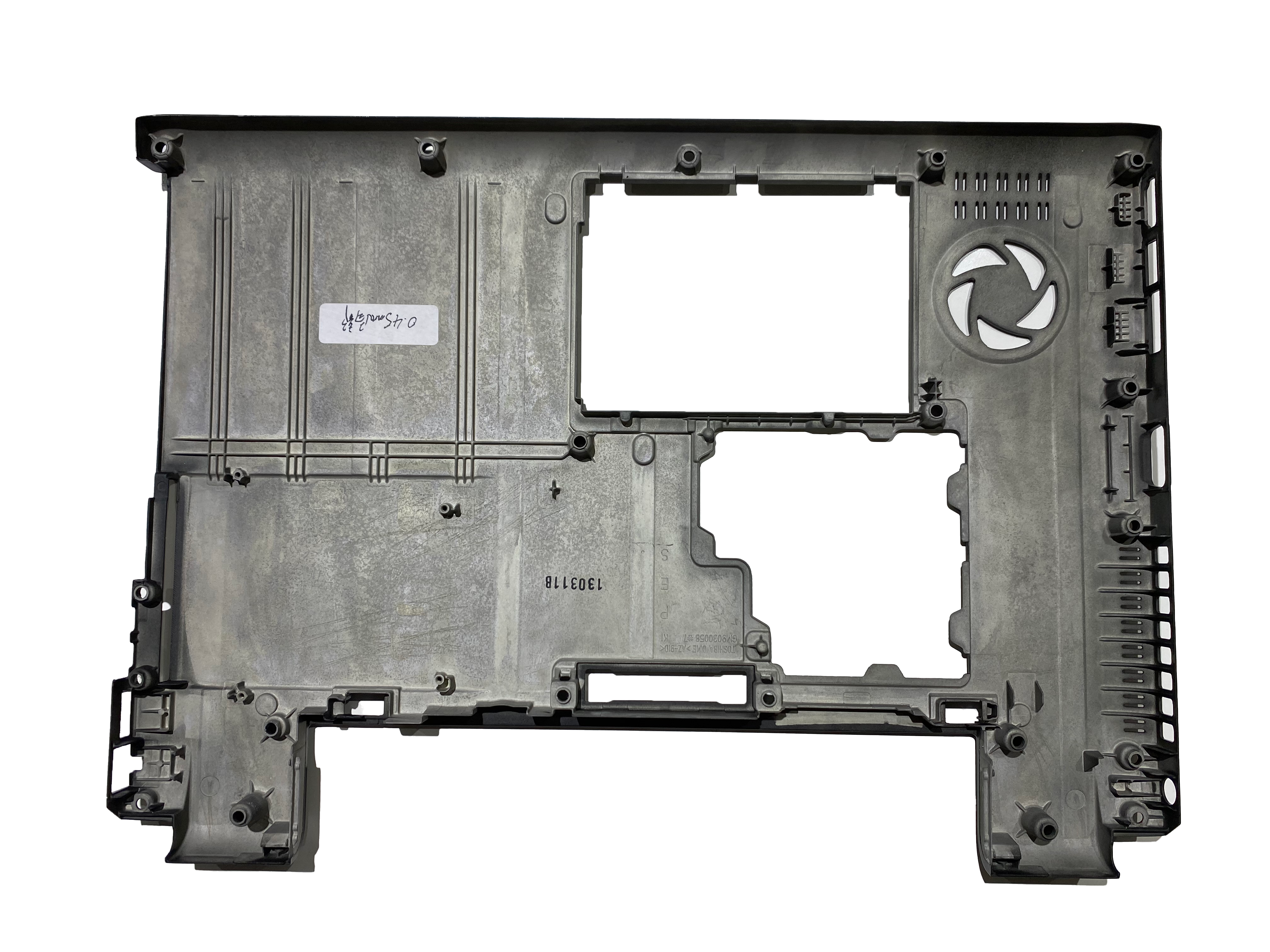

The Influence of Different Factors on the Quality of Die Castings

Die casting machine is the most basic equipment in die casting production. This is the condition for supplying energy and selecting optimal process parameters in die casting production. It is the guaranteed basis for realizing high pressure and high speed die casting characteristics and obtaining excellent die casting. In order to ensure the quality of die castings, avoid the occurrence of casting defects, save energy, and improve labor productivity and economic benefits, it is necessary to choose a reasonable type of die casting machine.

Of course, correct operation and maintenance to ensure the good performance of the die casting machine are extremely important measures in die casting production. According to the weight of the casting (including the runner, material handle and overflow groove), selecting the appropriate type of die casting machine and a die casting machine with good performance is a reliable guarantee for obtaining high quality die casting.

Influence of the performance of die casting machine on the quality of die castings

The main feature of the injection mechanism of modern die-casting machines is three-stage injection, that is, low-speed gas discharge in the injection chamber, high-speed filling cavity and continuous application of high pressure to liquid alloys, namely: two-stage speed and one-stage pressurization. The structural design of the domestic die-casting machine is basically the final design in the late 1970s and early 1980s. In the past 20 years, the overall performance has not improved significantly except for the relay system being replaced by PLC. The structural principle of injection molded parts is relatively advanced, but the adjustment of each parameter is manual, it is difficult to implement die casting process specifications, and the consistency of casting quality cannot be guaranteed.

The main factor affecting the reliability of the die casting machine is the substandard quality of hydraulic components. Die castings are easy to cause oil leakage and internal leakage of the hydraulic system, which affects the performance of the die casting machine.

Machine maintenance personnel often conduct regular inspections on die casting machines, which can be divided into four categories: daily inspection, weekly inspection, monthly inspection and semi-annual inspection. All kinds of small problems can be found and dealt with in time, so that the die-casting machine will never get sick and avoid serious damage to the machine.

The influence of the structure of the die-casting mold on the quality of the die-casting part

Die-casting mold is an important process equipment in die-casting production, which plays an important role in the smooth production and casting quality of production. Its important functions are:

- Determine the shape and size of the casting tolerance level.

- The gating system (especially the gate location) determines the filling state of the molten metal.

- The overflow exhaust system affects the discharge conditions of molten metal slag.

- Control and adjust the heat balance of the die casting process.

- It determines the surface quality and degree of deformation of the casting.

- The strength of the mold limits the maximum injection pressure.

- Affect business and production efficiency.

Usually the mold design will pay attention to the shape and dimensional accuracy of the casting, but often ignore the strength of the mold and casting system.

Conclusion

For more information about lpdc die casting process,sprue bush die casting,die casting ejector pins, we are glad to answer for you.