Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

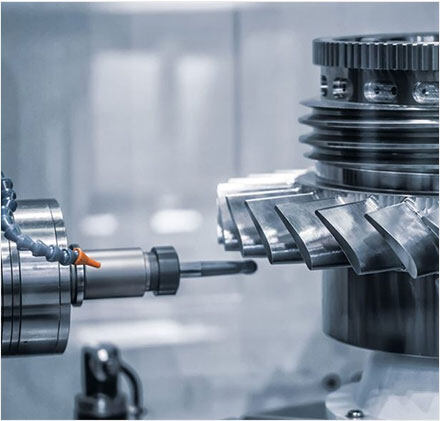

The Unique Use of Titanium Alloy in Precision Machining

As we all know, precision machining in the aerospace industry has high requirements for materials. Of course, one is to meet the particularity of aerospace equipment, and more importantly, it is due to the environmental impact of aerospace. Because of the special environmental impact, of course, the general materials on the market can not meet the needs of the environment, and it is bound to need some special materials to replace. Today, I'd like to introduce a commonly used material, titanium alloy, especially in aerospace. Why is this material used more? That has something to do with its characteristics.

Titanium alloy has a series of excellent physical and mechanical properties, such as low mass, high strength and thermal strength, hardness and high-temperature resistance, resistance to seawater and acid-base corrosion, etc. due to its small specific gravity, it can be used in any environment. In addition, its deformation coefficient is very small, so it has been widely used in aerospace, aviation, shipbuilding, petroleum, chemical industry, and other industries.

Just because titanium alloy has the above differences from ordinary materials, it also has great difficulties in precision machining. Many machining plants are unwilling to process this material and do not know how to process this material. To this end, we have sorted out some small skills to share with you!

Due to the small deformation coefficient, high cutting temperature, high tip stress, and serious work hardening of titanium alloy, the tool is easy to wear and collapse during cutting, and the cutting quality is difficult to guarantee.

How to do cutting?

When cutting titanium alloy, the cutting force is small, the work hardening is not serious, and it is easy to obtain a better surface finish. However, the thermal conductivity of titanium alloy is small, the cutting temperature is high, the tool wear is large, and the tool durability is low. Tungsten cobalt cemented carbide tools with small chemical affinity with titanium, high thermal conductivity, high strength, and small grain size should be selected, such as YG8, YG3, and other tools. In the turning process of titanium alloy, chip breaking is a difficult problem in processing, especially in the processing of pure titanium. To achieve the purpose of chip breaking, the cutting edge of the cutting part can be ground into a full arc chip curling groove, which is shallow in the front and deep in the back, narrow in the front and wide in the back, so that the chips are easy to be discharged outward so that the chips will not be entangled on the workpiece surface, causing a scratch on the workpiece surface.

The cutting deformation coefficient of titanium alloy is small, the contact area between the tool and chips is small, and the cutting temperature is high. To reduce the generation of cutting heat, the front angle of the turning tool should not be too large. The front angle of the cemented carbide turning tool is generally 5-8 degrees. Due to the high hardness of titanium alloy, to increase the impact strength of the turning tool, the rear angle of the turning tool should not be too large, generally 5 degrees. To strengthen the strength of the tooltip, improve the heat dissipation conditions, and improve the impact resistance of the tool, The negative inclination angle with a large absolute value is adopted.

The reasonable cutting speed should not be too fast, and the use of titanium alloy special cutting fluid cooling in the processing process can effectively improve the tool's durability and select a reasonable feed rate.

Drilling is also commonly used. It is difficult to drill titanium alloy, and knife burning and drill breaking often occur in the processing process. The main reasons are poor grinding of the bit, untimely chip removal, poor cooling, and poor rigidity of the processing system. Depending on the diameter of the drill bit, the transverse edge is ground narrow, and the width is generally 0.5mm, to reduce the axial force and reduce the vibration caused by resistance. At the same time, at a distance of 5-8 mm from the tip of the bit, grind the bit edge band narrow, leaving about 0.5 mm, which is conducive to the bit in chip removal. The geometric shape must be ground correctly, and the two cutting edges must be symmetrical, to prevent the drill bit from cutting with only one edge, and the cutting force is all concentrated on one side, which will cause premature wear of the drill bit, and even cause edge collapse due to slipping. Always keep the blade sharp.

When the blade becomes blunt, stop drilling immediately and regrind the bit. If you continue to forcibly cut with a blunt drill bit, the drill bit will soon be burned and annealed due to high friction temperature, resulting in a scrap of the drill bit. At the same time, it is also the thickening of the hardened layer of the workpiece, which increases the difficulty of re-drilling and the number of times grinding the drill bit in the future. According to the requirements of drilling depth, the length of the drill bit should be shortened as far as possible, and the thickness of the drill center should be increased to increase the rigidity, to prevent the edge from collapsing due to shaking during drilling.

We are the precision machining companies, for more information about cnc swiss precision machining, china cnc precision machining, plz feel free to contact us.