Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

The Difference between 3 axis, 4 axis and 5 axis Machining

Milling is an important technology for CNC precision machining, which is used in medical, aerospace, optical, and mechanical components. Milling uses a rotating tool to remove material from the workpiece by feeding the workpiece at an angle to the axis of the tool. The axis of the milling machine determines the type of workpiece and the position of completion on the workpiece. Today, let's take a look at the differences between 3,4, and 5-axis machining.

What is 3-axis machining?

Although this is a more basic processing process, according to the production scale, workpiece requirements, accuracy and finishing constraints, materials used, and retention capacity, 3 axis processing may be the ideal choice for your processing project.

What is 4-axis machining?

4 axis milling involves the same process involved in 3 axis machining, in which cutting tools are used to remove material from the workpiece to produce the desired shape and profile. However, in the case of 4 axis machining, milling is performed on the additional axis. The 4 axis NC machine tool runs on the X, y, and Z axes, just like the 3 axis machine tool, but it also includes rotation around the X axis, which is called the axis. This is the fourth axis added to our processing process. In most cases, the workpiece will rotate to allow cutting around the b-axis.

4 axis milling is useful when you need to make holes and cuts on the side of a part or around a cylinder. They can provide fast and effective work based on computer digital input to obtain accurate results.

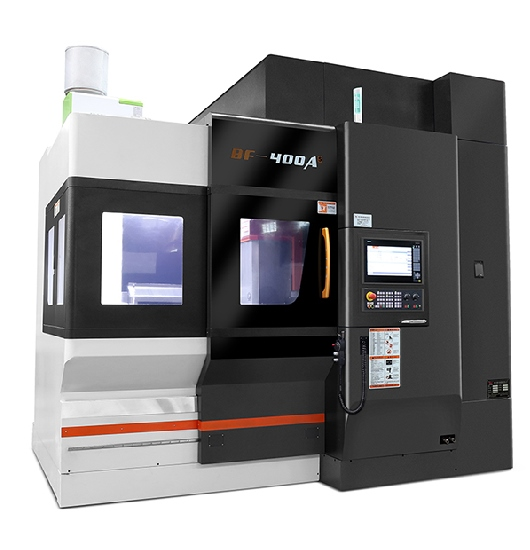

What is 5-axis machining?

5 axis machining involves all shafts of 4 axis machining, with additional rotating shafts. 5 axis milling machine is a better CNC milling machine in the market at present, which can create accurate and complex parts for artificial bone, aerospace products, titanium parts, oil and natural gas machinery parts, automobile molds, medical treatment, construction, and military products. The 5th axis of the 5 axis milling machine revolves around the b axis and rotates around the Y axis in the x-y-z plane. This multi-dimensional rotation and tool movement make the b-axis have rare accuracy, smoothness, and speed in production parts. 5 axis machining can create very complex parts, which is why it is very important for high-end applications such as aerospace applications.

However, 5 axis machining is also becoming more and more popular because it provides a one-step machining option (shortening the lead time), allows better access to the part geometry, and improves tool life and process efficiency by tilting the workbench. The ideal cutting position.

Make a purchase of 3 axis machining, 4 axis cnc mill for sale, 5 axis machining near me from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.