Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

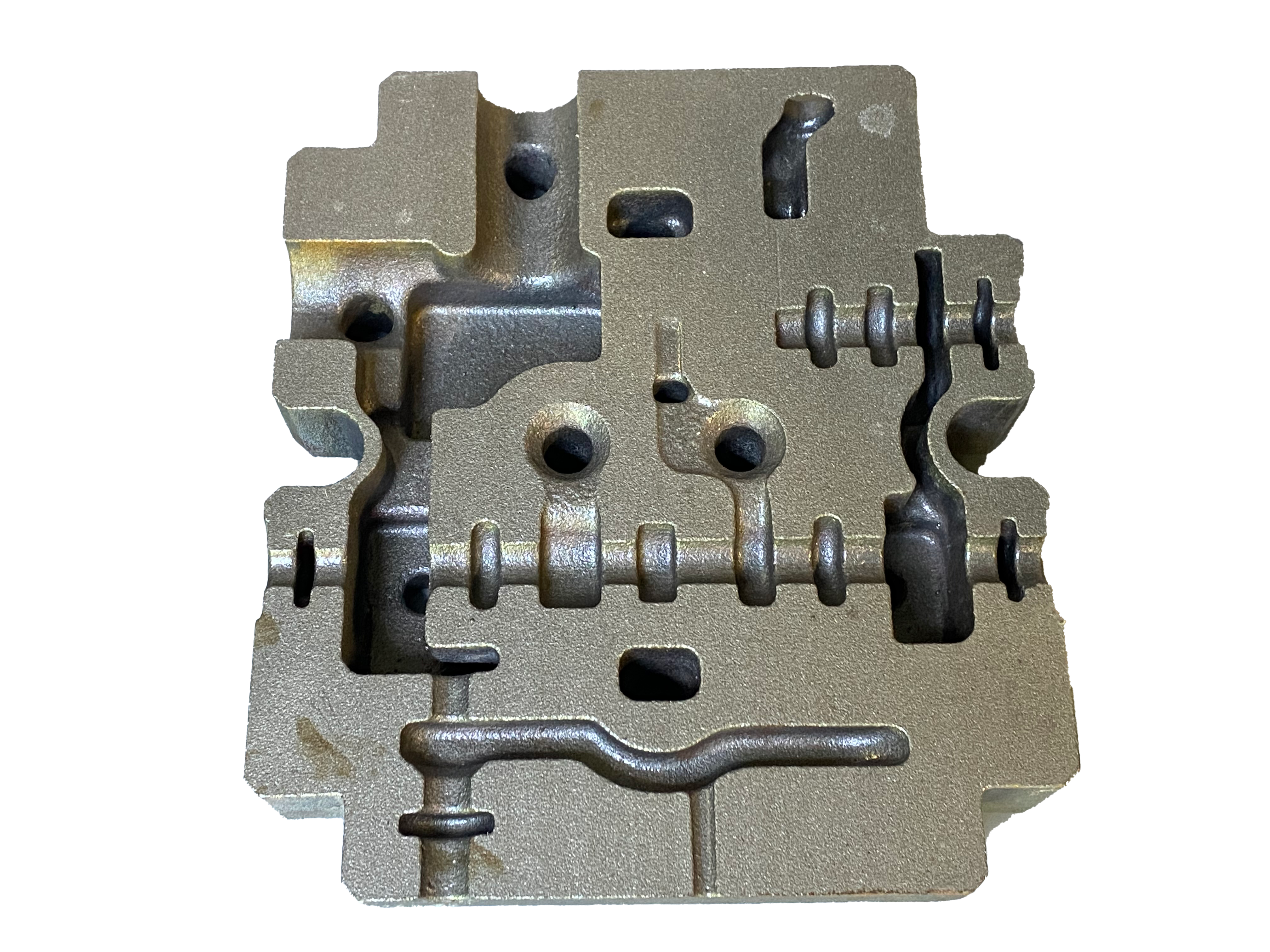

Stainless Steel Precision Casting Is a Casting Process with Little or No Cutting

Stainless steel precision casting is a casting process with little or no cutting, and it is an excellent process technology in the foundry industry. In the production process of stainless steel precision casting, the sulfuric acid oxide film is an important factor affecting the high purity and transparency of the stainless steel casting oxide film. The porosity, purity, thickness and sealing quality of stainless steel precision casting will directly interfere with the mirror effect of the casting.

Stainless steel precision casting is a casting process with little or no cutting

The essence of stainless steel precision casting is to apply a large mechanical pressure to the liquid metal quantitatively poured into the mold cavity to make it form, crystallize and solidify to obtain a part blank. This process method has also been called "liquid metal die forging", "liquid metal stamping", "liquid metal forging", "punch pressure crystallization" and so on.

There are many technological forms of stainless steel precision casting. According to the characteristics of liquid metal filling and extrusion force during molding, it can be divided into plunger pressure, direct punch extrusion, indirect punch extrusion (also divided into upper extrusion method), and down extrusion method) and so on. Plunger squeeze casting is mainly suitable for thick-walled castings and ingots with simple shapes; direct extrusion is suitable for castings with thin walls and complex shapes; indirect extrusion is suitable for castings with large output and complex shapes.

What is the wall thickness of stainless steel precision casting steel castings?

The mechanical properties of stainless steel precision casting are higher than those of cast iron in the process of use, but the performance of such materials will be worse than that of cast iron. be taller.

There are many problems that need to be paid attention to in the process of processing, mainly because the flow properties of molten steel are relatively poor. The wall thickness of steel parts should not be less than 8mm.

The structural force of the gating system is relatively simple, and the section size of the equipment in the process of use should be larger than that of cast iron, so that the hot casting mold or dry casting mold can also be used in the process of processing.

The temperature guarantees the good fluidity of the melt during the transfer process. The selection of the stainless steel precision casting temperature should be determined according to the distance of the transfer, the cooling condition of the transfer process, the alloy, the specification, the flow rate and other factors. The stainless steel precision casting temperature is higher than the alloy liquidus line. The temperature is 50 to 110°C higher.

The production temperature can ensure that the melt will have good fluidity during the casting process. In the process of selecting the casting temperature, the equipment needs to be determined according to the distance of the casting and the cooling of the casting process.

Conclusion

For more information about lost wax precision casting,investment & precision castings,aluminum precision casting, we are glad to answer for you.