Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

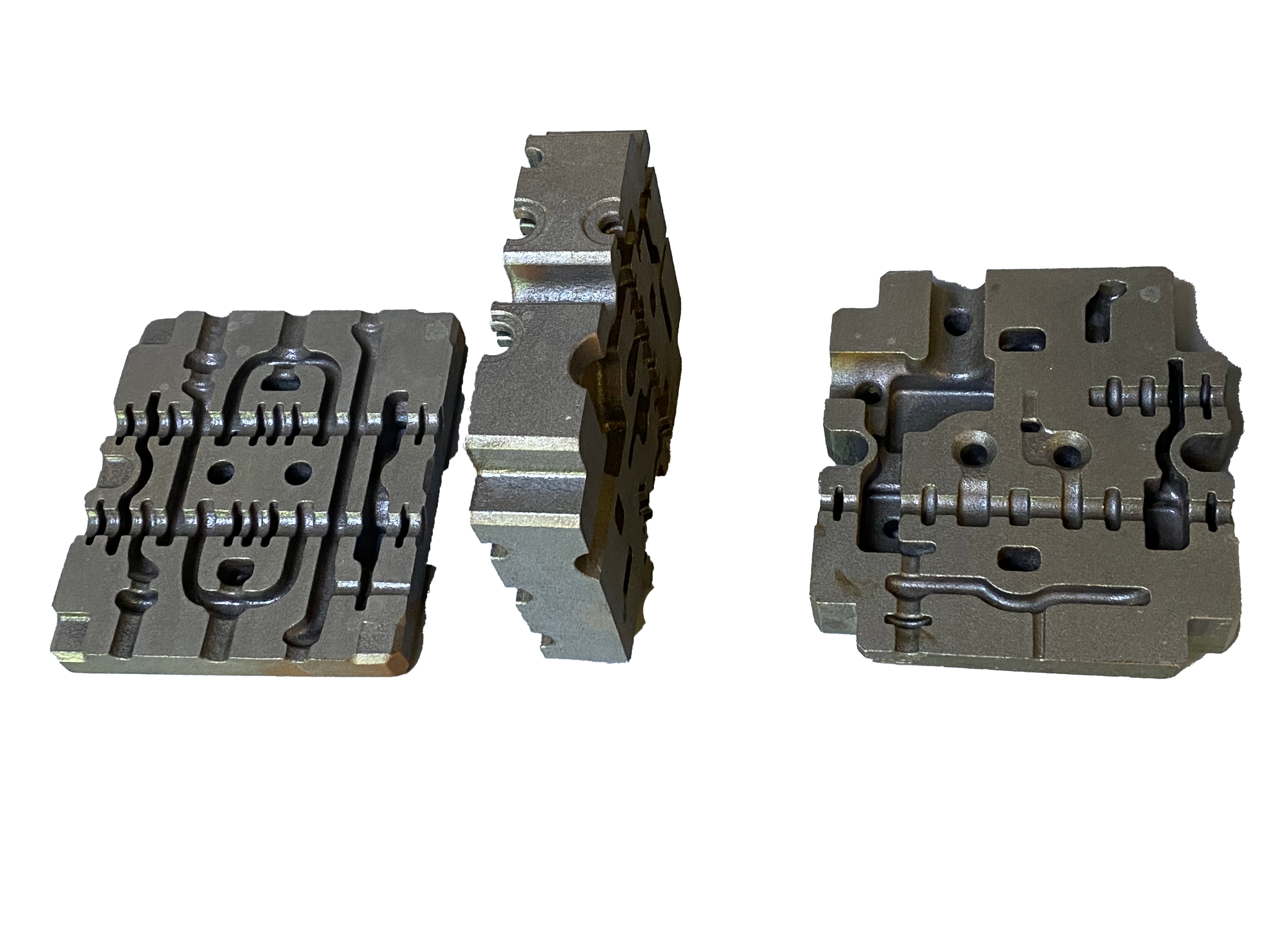

Installation Steps of Precision Casting

The melting point of precision casting steel is high, and its casting temperature is relatively high. At high temperature, molten steel and mold raw materials interact with each other, and it is easy to show the disadvantage of sticking sand. Therefore, artificial quartz sand (property: silicate mineral) with higher refractoriness should be used as the casting mold, and the coating made of quartz powder or zirconium sand powder should be brushed on the surface of the casting mold.

Precision casting installation steps

Considering that the shortening of cast steel is much higher than that of cast iron, in order to prevent the defects of shrinkage cavities and shrinkage porosity of castings, most of the methods such as riser and cold iron and subsidies are used in the casting process for successive condensation. In addition, in order to prevent stainless steel (stainless acid-resistant steel) castings from showing shrinkage holes, shrinkage porosity, pores and cracks.

It should make its wall thickness uniform, prevent sharp and right-angle structures, add sawdust to the casting sand, add coke to the core, and use hollow cores and oil sand cores to improve the sand or core's concession and air permeability. Considering the poor fluidity of molten steel, in order to prevent cold insulation and pouring defects of stainless steel castings, the thickness of stainless steel castings should not be less than 8mm; the structure of the casting system needs to be simple and the cross-sectional standard is larger than that of cast iron.

Choose dry casting mold or hot casting mold; increase the casting temperature appropriately, generally 1520-1600 ℃, considering that the casting temperature is high, the superheat degree of molten steel is large, and the liquid state can be maintained for a long time, and the fluidity can be improved. Precision casting refers to the general term for the production process of standard castings. Compared with the traditional sand casting production process, the casting size of precision casting is more accurate and the surface finish is better.

Classification of precision casting

It includes: investment casting, ceramic casting, sand casting, pressure casting, lost wax casting. Precision casting is also called lost wax casting. Its products are precise, complex, and close to the shape of the parts. It can be directly selected without processing or with little processing. It is a near-net-shaped process. However, if the pouring temperature is too high, it will cause defects such as coarse and hard crystals, thermal cracking, pores and sticky sand.

Therefore, the casting temperature of general small, thin-walled and chaotic castings is about the melting point of steel + 150 °C; the casting temperature of large and thick-walled castings is about 100 °C higher than its melting point. Silica sol precision casting production technology is used for precision casting. We have a complete set of equipment and equipment for raw material quality component inspection (inspection and testing).

The production equipment of precision casting is all intelligently controlled from wax melting, injection, dewaxing, roasting and casting. Each furnace of molten steel with different raw materials uses an element analyzer to perform on-site raw material composition detection and analysis. Precision casting must not be carried out for those with defective or too high raw material components, which ensures the quality and reliability of the equipment from the source.

Conclusion

For more information about precision lost wax casting,carving wax for lost wax casting,lost wax casting steel, we are glad to answer for you.