Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nouvelles

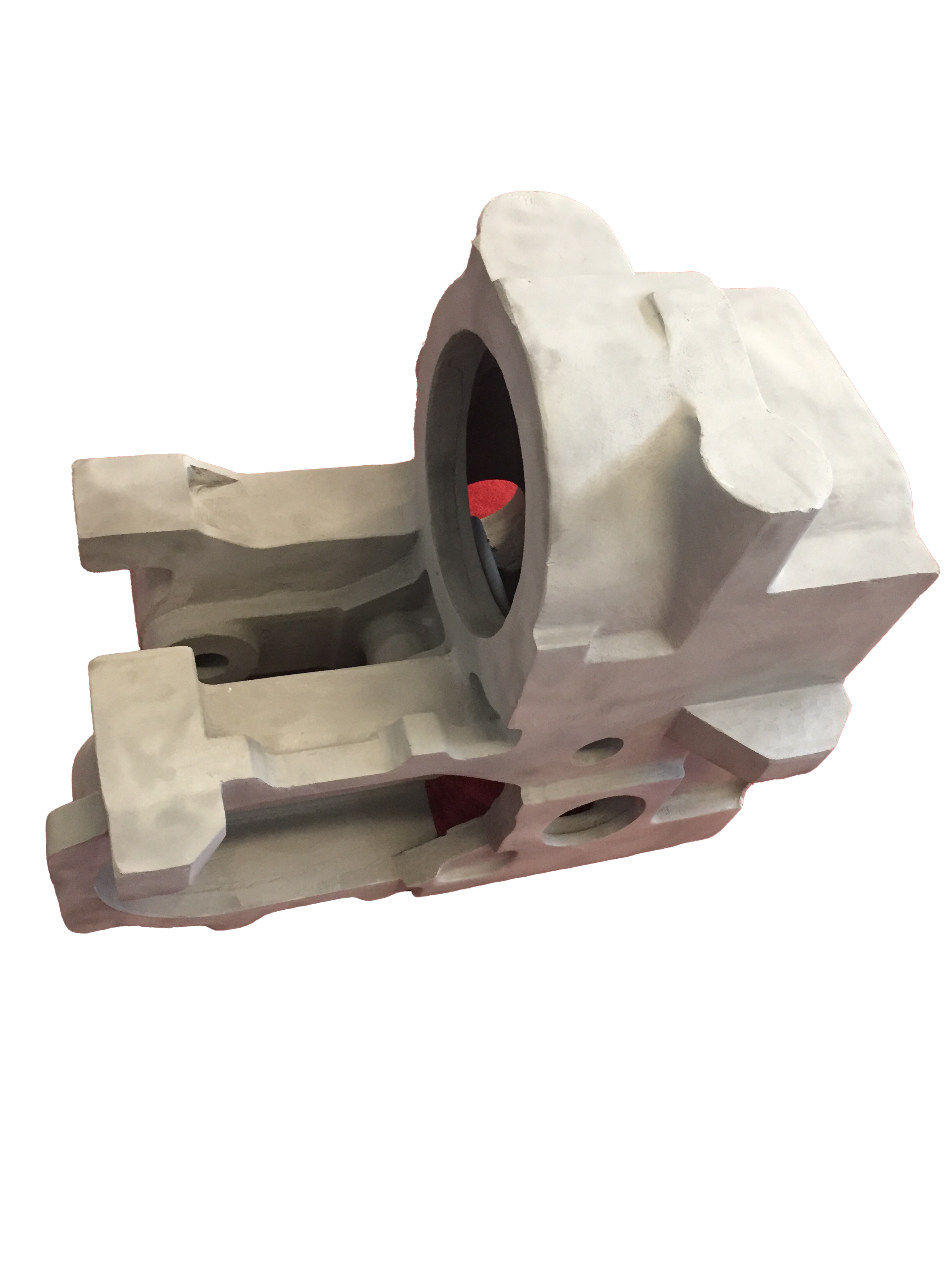

Analysis of Blistering Defects in Die Castings

Zinc alloy die-casting parts are generally used in various decorative design levels at this stage, such as furniture accessories, electronic device parts, architectural decoration design, shower room accessories, lighting parts, small toys, bow tie buckles, belt buckle heads, various Various metal material decorations, etc., so the requirements for casting process performance are high, and it is required to have excellent metal surface treatment characteristics. The most common disadvantage of zinc alloy die castings are surface blistering.

The main disadvantage is that there are blisters on the surface of the casting.

- The aluminum die-casting will find it.

- It will appear after grinding and polishing or production processing.

- Appears after the oil pump or electroplating process.

Cause

- The hole is caused by: mainly the air outlet and the gathering system. The air outlet is usually annular, and the gathering is most irregular.

(1) Causes of vent holes:

- During the whole process of filling and condensing the metal material liquid, due to the intrusion of the vapor, holes are formed on the surface or inside of the casting.

- Invasion of vapors evaporating from architectural coatings.

- The aluminum alloy liquid contains too much air and dissolves when it condenses.

When the vapour in the die, the volatilized vapour from the architectural paint, and the vapour condensed and dissolved by the aluminum alloy, when the exhaust pipe of the abrasive tool is not good, it is finally left to the air outlet generated in the casting.

(2) Causes of shrinkage:

- During the whole process of the metal material liquid coagulation, the shrinkage is caused because the volume becomes smaller or the final condensation position cannot be fed by the metal material liquid.

- The castings or castings with uneven thickness are overheated, resulting in slow condensation at a certain position, and concavities are formed on the surface when the volume is closed.

Due to the existence of air vents and shrinkage porosity, when the metal surface of the casting is processed, the holes will enter the water, and when the baking and electroplating processes are carried out, the vapor in the holes will be deformed by heat. Or the water in the hole will become steam, and the volume will expand, thus causing the surface of the casting to blister.

Brief introduction of die casting process

Aluminum die-casting machines can be mainly divided into two different types: hot-chamber die-casting machines and cold-chamber die-casting machines. The difference depends on how much energy they can handle. The typical working pressure range is between 400 and 4000Kg.

Poor electroplating process can be caused by factors such as electroplating and casting process performance.

Castings should ensure that the process performance is excellent, and there should be no defects such as looseness, cracks, air vents, bubbles, shrinkage porosity, cold lines, pinholes, etc. Otherwise, the surface of the castings is prone to blisters after the electroplating process, and the electroplating process layer and the base material are freed.

When grinding and polishing before the electroplating process, be careful not to grind too much. During the whole process of solidification of the casting, a high-density chilled layer is formed on the surface layer due to chilling, and the internal mechanism will have defects such as air vents and shrinkage porosity. It is not necessary to grind off this excellent surface during grinding, otherwise black spots, bubbles, etc. will appear during the electroplating process.

In addition, the polishing cloth wheel does not have to be pressed too tightly and overheated, so as to prevent the abrasive liquid from sticking to the product, resulting in poor electroplating process for the product.

Conclusion

For more information about die casting mold parts,aluminium die casting components,die casting in automotive industry, we are glad to answer for you.